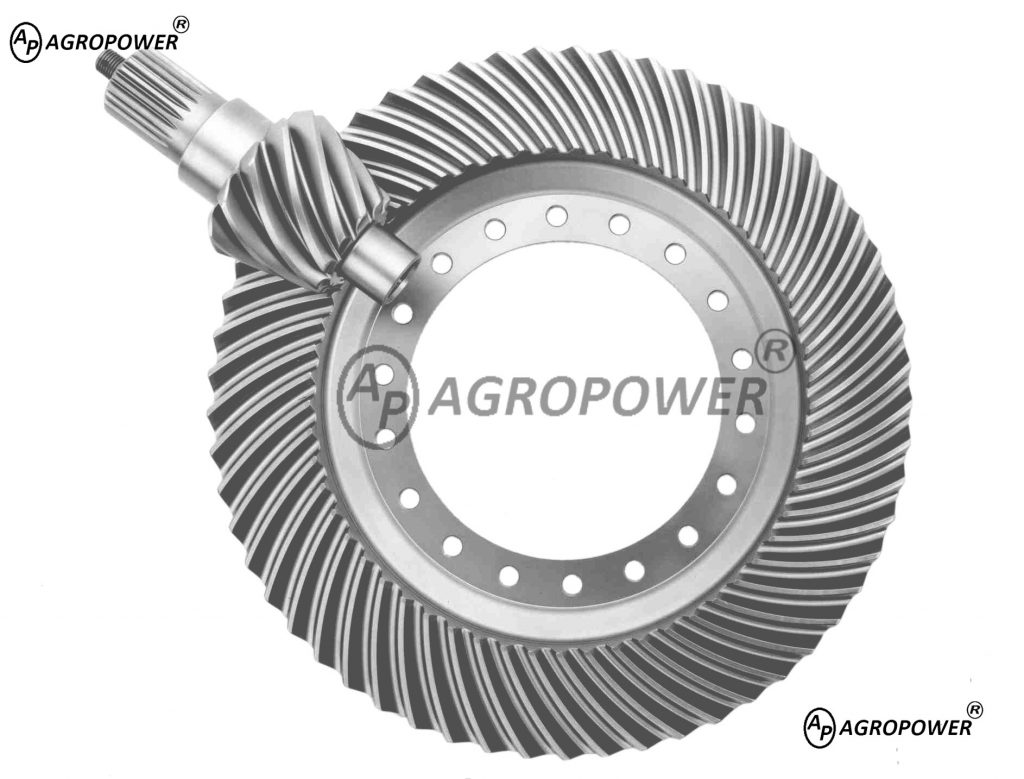

Miter Gears

Miter Gears Miter Gears are bevel gears put together with equal numbers of teeth and axes that are usually at right angles. Miter is the surface forming the beveled end or edge of a piece where a miter joint is made. These gears are cut with a generated tooth form that has a localized lengthwise tooth bearing. They …